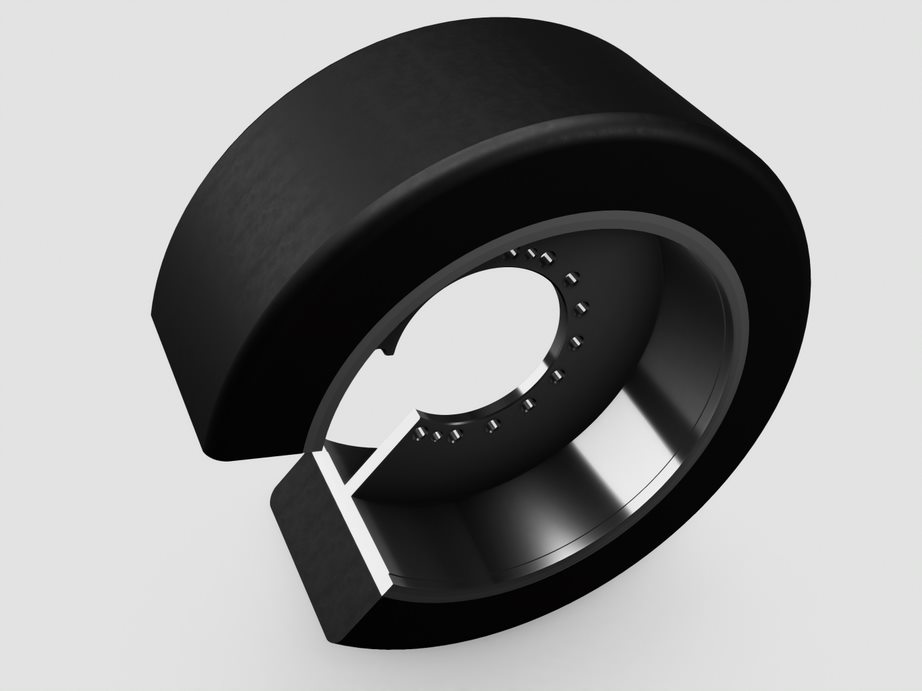

All laminated wheels from EVERPADS feature 100% natural rubber with a special rubber compound, and can be customized to fit most industrial and commercial purposes. Our laminated wheel products never fall off, it provides supreme quality for longevity. The continuous high-standard laminations that wound over standard macerated centers produce more excellent resistance to fraying. This results in more impact strength that is higher than the conventional laminated wheels.

Technology

- The manufacturing process comprises 100% natural rubber.

- The material used to produce the steel ring is mainly alloy steel material.

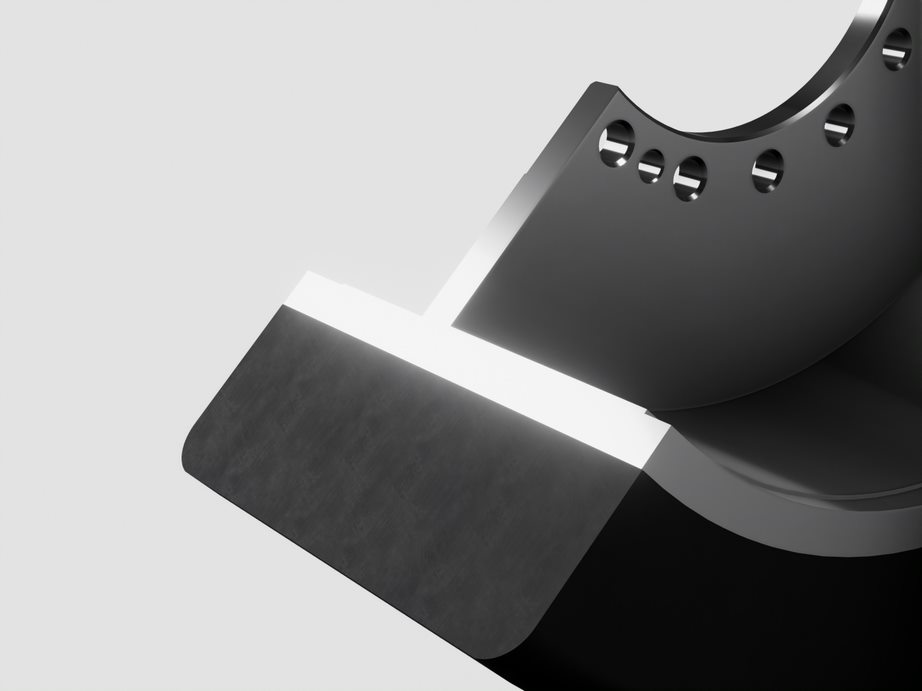

- A proper production process that enhances the rubber adhesion due to the electroplating anti-rust treatment.

- A properly done sandblasting treatment that ensures the colloid is put in place without falling off. EVERPADS combination with the key technology formula E makes it your profitable choice.

- The formula E solution of EVERPADS rubber wheel controls the rubber temperature at 63℃ / 145.4℉, This keeps the tire from aging and losing property capacity(tearing strength and abrasion resistance) too quickly. It also extends the wheel life span.

- Test with pulling test: it can bear 800kn, increasing 54% of strength from the last version.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)