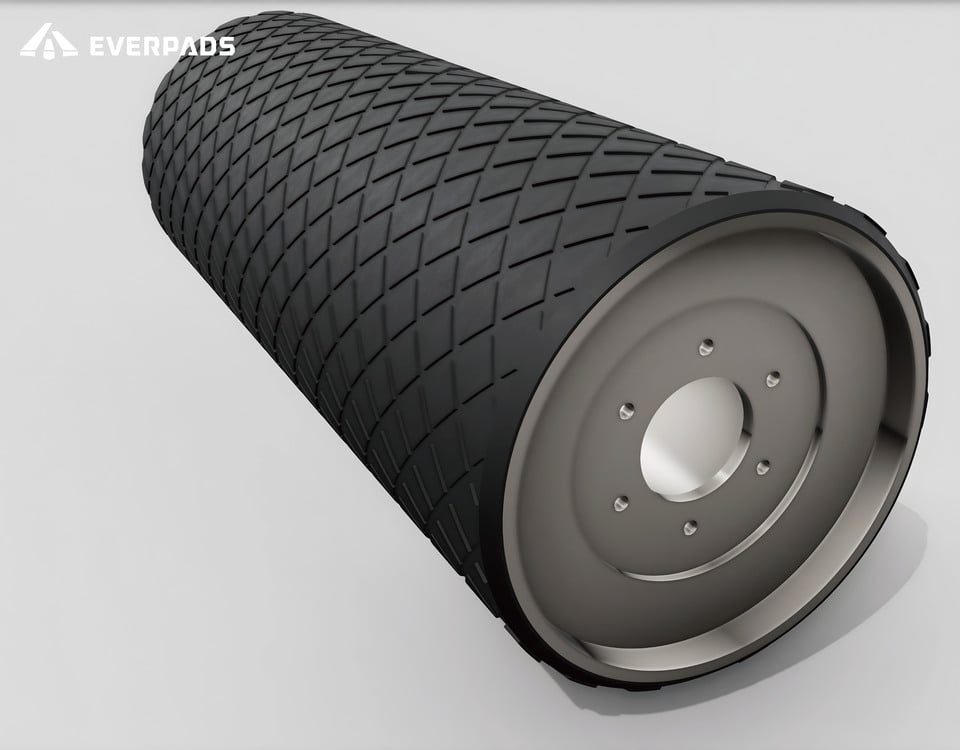

This type of drive roller is found in applications that necessitate enormous contact and grabbing friction forces during operation. It is cylindrically shaped and patented with heavy-duty rubber with a special adhesive solution to improve its lifespan.

No matter the conveyor system loading pressure, the drive roller features a high-quality rubber that is capable of handling it. During operation, you are sure of high energy efficiencies especially in the conveyor system of cold milling.

Drive rollers in this listing can be selected for cold planers, they are manufactured with a load alignment technique, to enable load accumulation during operation.

EVERPADS drive rollers feature long-lasting anti-asphalt rubber due to the unique thickening manufacturing process it undergoes. The steel structure process guarantees smooth operation. Well sealed to ensure life- maintenance-free during usage.

Key Features

-

The stable steel structure guarantees long term usage.

-

Very durable and contains high-grade rubber that is permanently bound with metal.

-

Provides adequate power delivery due to the sufficient material with higher friction it possesses.

-

The specifically designed surface prevents asphalt particles from gluing together.

-

The body roll is accurately formulated for the exact centering of the belt.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)