Tired of Track Roller Oil Leaks on Your Asphalt Milling Machine? Here’s Why They Happen—and How to Stop Them

18. Nov. 2024

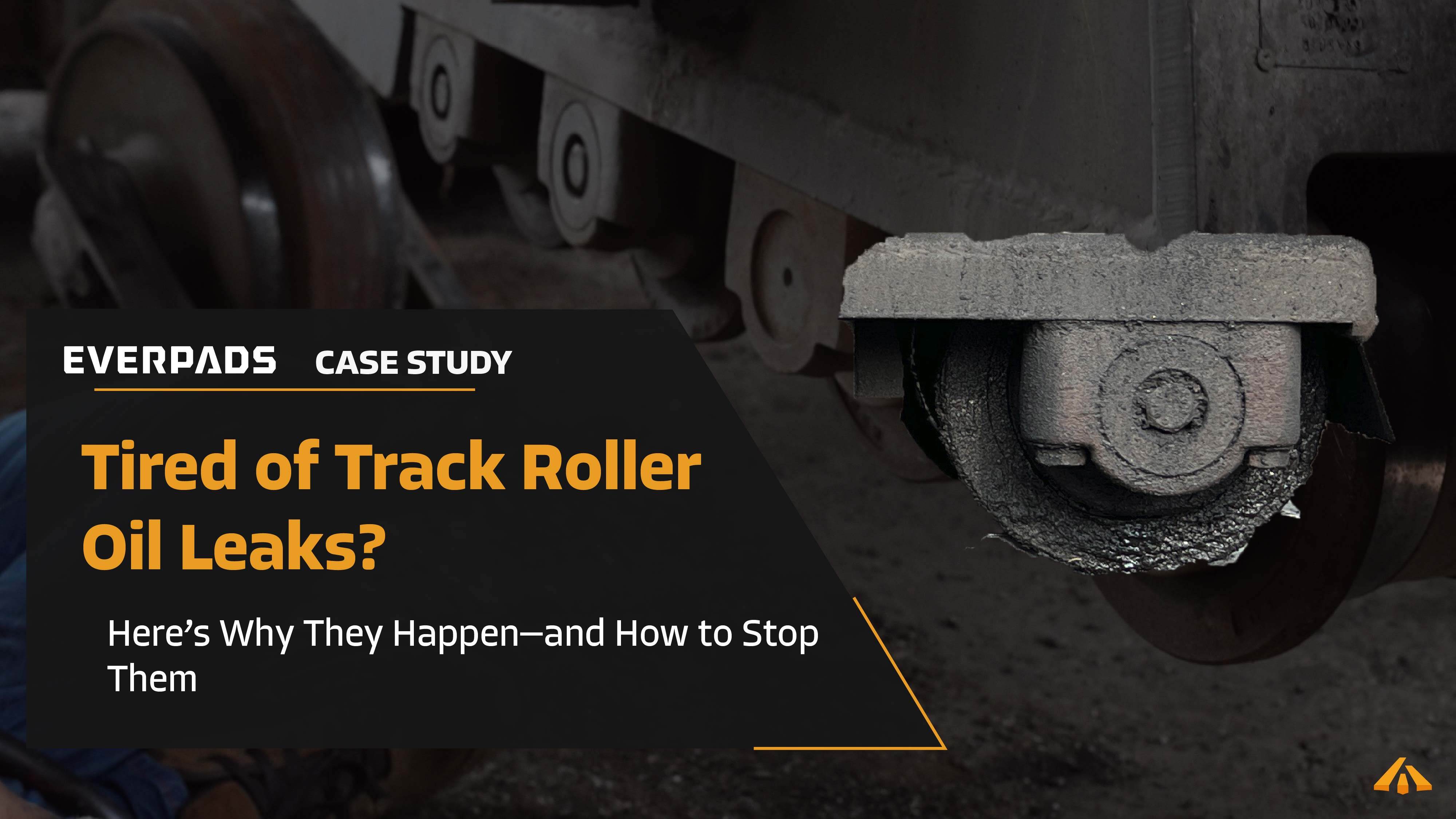

Oil leakage is the leading cause of premature failure in track rollers and idlers, forcing most products on the market to be replaced within a year and a half—even when the roller body itself still has plenty of life left. In theory, if oil leakage were prevented, these conventional rollers for Cold Milling Machine could last around two years, maximizing their wear potential. But for years, customers have been dealing with roller breakage, only to find their suppliers and dealers offering no real solutions.

In this post, we’ll explain why oil leaks happen, why traditional rollers fail prematurely, and what can be done to truly solve this problem.

Typical oil leakage of a traditional track roller

Typical oil leakage of a traditional track roller

Table of Contents:1. The Costly Problem of Oil Leakage in Track Rollers

2. Why Oil Leaks Happen in Traditional Track Rollers

3. Everpads’ Solution: Designed to Last

4. Why Don’t Other Manufacturers Fix This Issue?

5. Our Commitment to Contractors

The Costly Problem of Oil Leakage in Track Rollers

Many track rollers and idlers on the market, including those used in cold planers, are equipped with conventional oil-sealing systems and internal design flaws that simply can’t handle the capacity demands of heavy machinery. These issues cause the lifecycle of these products to be cut short, often resulting in sudden, unpredictable failures. Not only does this add maintenance headaches for contractors, but it also leads to higher replacement costs over time.

Our products, however, feature advanced oil-sealing systems and precision positioning adjustments that significantly enhance their functionality and durability.

For contractors, these oil leaks become a costly burden, causing downtime, increased maintenance, and more frequent replacements—all factors that interrupt job schedules and add unnecessary expenses.

Design and Construction Factors: The Root of the Problem

While cold planers and milling machines are engineered for optimal performance, track roller oil leaks often trace back to design and construction issues, particularly in the spare parts sector. Manufacturing imperfections, such as poorly sealed outer rings, can allow contaminants to infiltrate and damage the bearing. Similarly, cages that aren't built to endure high loads over prolonged operations can experience accelerated wear, ultimately leading to oil leaks.

This discrepancy becomes evident as top brands focus their R&D efforts on machinery optimization, often neglecting the finer details of spare part durability. This is where Everpads stands out—delivering high-quality spare parts designed to address these overlooked vulnerabilities, ensuring both reliability and extended lifespan for your equipment.

Why Oil Leaks Happen in Traditional Track Rollers

Traditional track rollers often rely on a floating seal or duo cone seal system. This system uses a rubber O-ring, positioned alongside the floating seal, to create a tight seal and prevent oil from leaking. The design depends on both end caps being properly tightened to ensure the seal remains effective. However, several factors contribute to a high risk of oil leakage over time, compromising the system's reliability and performance.

In the road construction industry, ensuring the highest quality parts is crucial for minimizing risks and extending the lifespan of the equipment.

Key reasons for oil leakage include:

- Inherent Seal Design Limitations: The floating seal system is inherently prone to oil leakage, especially under harsh conditions or extended use, as its sealing capability can degrade over time.

- Machining Inaccuracies: If the end caps are not machined to precise tolerances, gaps can form between the sealing surfaces, reducing the effectiveness of the seal.

- Rubber O-Ring Wear: Over-tightening the end caps can place excessive pressure on the rubber O-ring, causing accelerated wear and eventual leakage.

- Impact of Uneven Surfaces: When the machine operates on uneven terrain, the lateral movement can damage the seal, leading to oil leaks and reduced performance of your asphalt planers.

Everpads’ Solution: Designed to Last

To effectively solve the challenges associated with traditional sealing systems, we developed a unique approach. Our advanced sealing system is fully integrated with the roller body, forming a unified structure that operates independently from the installation end caps. Unlike conventional designs where end caps play a dual role—providing structural support and maintaining the oil seal—our system separates these functions. The end caps in our design are solely responsible for securing the roller onto the track chain, without impacting the integrity of the seal.

E-Generation Track Roller Design

E-Generation Track Roller Design

This innovation eliminates the common issues found in traditional floating seal systems, such as seal degradation due to lateral movement or wear from excessive tightening. By decoupling the sealing mechanism from the installation components, we ensure consistent performance and significantly reduce the risk of oil leaks, even under harsh operating conditions.

Here’s what makes Everpads’ solution unique:

- Patented Oil-Sealing System: Nearly eliminates oil leakage, addressing the problem at its core by maintaining consistent performance and reducing wear.

- Separation of Functions: Installation end caps are dedicated solely to mounting, preventing stress on the seal and enhancing durability.

- High-Grade Forged Alloy: Provides exceptional durability, extending the roller's service life to three years.

- Reduced Maintenance Costs: With fewer leaks and a longer lifespan, contractors experience minimized downtime and lower replacement costs.

- Superior Performance on Uneven Terrain: The integrated design withstands lateral movement, ensuring reliable operation without seal damage.

By addressing the root causes of oil leakage and prioritizing long-lasting performance, Everpads offers a solution that outperforms traditional products, giving contractors peace of mind and reducing the frequency of replacements.

E-generation Track Roller

E-generation Track Roller

Why Don’t Other Manufacturers Fix This Issue?

Many manufacturers choose not to address track roller failures because they assume that most contractors will replace the entire undercarriage system together. They see little value in enhancing track roller durability if the other components in the system don’t have a similarly extended lifespan. Upgrading individual components like the track rollers would require significant investment, and without improvements across all parts, they believe strengthening just the track rollers alone isn’t practical or worthwhile.

At Everpads, we take a different approach. We’ve conducted extensive research to identify the common causes of early wear and failure specifically in track rollers, as well as in all the components of the undercarriage. By addressing these vulnerabilities, we’ve developed patented solutions and upgraded our materials and production methods, resulting in a comprehensive improvement for our entire track system. Now, each component is designed to overcome early wear issues and is built with materials and structures optimized to deliver a three-year lifespan.

This commitment means that our customers receive a high-performance track roller solution designed to endure the demands of heavy machinery without compromise, providing a reliable, long-lasting solution for contractors looking to minimize downtime and maintenance costs.

Our Commitment to Contractors

At Everpads, we believe that true value means solving real challenges, not just maximizing profit. Every product we create upholds this principle because we understand the impact of reliable equipment with competitive prices on a contractor’s operations. You can tell a lot about a brand by the insights it shares and the lengths it’s willing to go to ensure quality.

Now You Know Oil Leaks Are Built into Traditional Rollers—Isn’t It Time for an Upgrade?

Oil leakage in traditional track rollers is an inherent flaw that leads to premature failures and costly replacements. By investing in a solution that nearly eliminates this problem, Everpads offers contractors an option that’s built to last and perform.

Choose Innovation. Choose Everpads.

Supplement Info:

Understanding Track Rollers and Idlers

Track rollers and idlers are indispensable components in a wide range of industrial applications, including construction, mining, and manufacturing. These components play a crucial role in ensuring the smooth operation of machinery and equipment, reducing friction, and minimizing wear and tear.

Track rollers are specialized rollers designed to follow the curvature of a cam or track. They are typically manufactured with radial ball bearings or tapered roller bearings, which allow them to withstand light to moderate radial loads. These bearings are essential for accommodating combination loads and improving upon traditional cam followers, ensuring the efficient operation of the machinery.

Idlers, on the other hand, are designed to support and guide conveyor belts or other moving parts. By reducing friction and wear on the system, idlers help maintain the smooth and efficient movement of materials. In construction, for example, idlers are critical for guiding conveyor belts that transport asphalt, gravel, and other materials to trucks and other equipment.

In summary, both track rollers and idlers are vital for the performance and longevity of industrial machinery. Their ability to reduce friction, support loads, and guide moving parts makes them essential components in various applications, from construction to manufacturing.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)