Precision-Designed for Large Machines in Medium-to-Hard Terrain

Choosing the right milling teeth goes beyond tungsten carbide selection, manufacturing quality, alloy composition, and patented designs—all of which Everpads upholds at the highest industry standards.

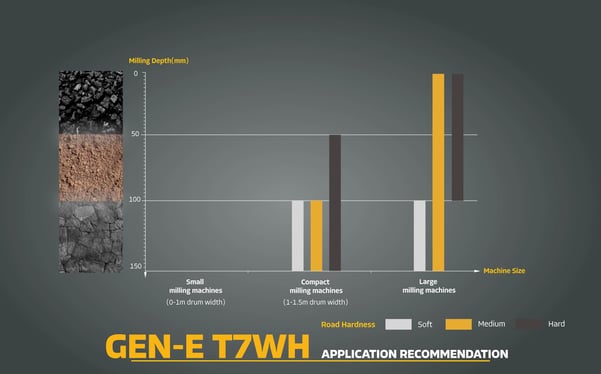

Once these basics are covered, the real challenge begins: choosing a milling tooth optimized for specific site conditions. That’s where the GEN-E T7WH comes in—engineered specifically for large machines (2m milling width) operating in 0-100mm depth and medium-to-hard asphalt conditions.

Ultimate Durability Choice for Compact Machines in Hard Conditions

For compact machines (1.2m-1.5m milling width) operating in medium-to-hard terrain, durability is the key to reducing downtime and maximizing efficiency. That’s why GEN-E T7WH is engineered to withstand the toughest milling conditions, delivering superior longevity and cutting stability.

While T7WH is optimized for large machines (2m milling width) in 0-100mm depth and medium-to-hard asphalt conditions, it is also highly recommended for:

- Large machines (2m milling width) in 100-150mm depth and soft-to-medium asphalt conditions

- Compact milling machines (1-1.5m milling width) in 50-100mm depth and extreme hard asphalt conditions

- Compact milling machines (1-1.5m milling width) in 100-150mm depth and all hardness.

Note: This Guide is for road maintenance projects.

📌 Want to learn how to evaluate milling teeth from different suppliers? Read our expert guide: "How to Assess Milling Teeth Design and Materials Across Different Brands."

This blog is perfect for:

- Contractors and Operators looking for the most Durable and cutting-efficient milling teeth for small and Compact milling machines.

- Project Managers seeking to optimize milling performance while minimizing downtime and replacement costs.

I. How T7WH Stands Out from Competitor Products

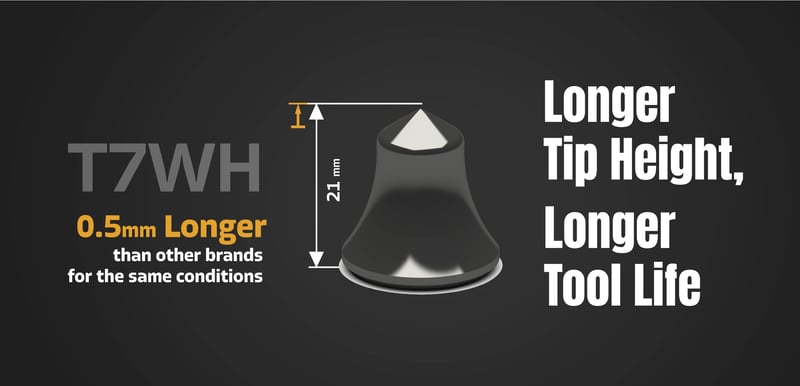

Unlike competing products designed for similar conditions, the T7WH features a tungsten carbide tip with the same thickness as competitor models but with a longer overall height and a wider base:

1. Incomparable Cutting Efficiency – The T7WS significantly leads in cutting force compared to leading brands in this product segment.

2. Extended Tool Life – A longer tungsten carbide tip means more usable material before replacement is required, reducing downtime.

3. Stronger Toolholder Protection –

A 10% wider wear plate design extends toolholder lifespan by 15%.

4. Stronger Fracture Resistance – While longer tungsten carbide tips are traditionally more prone to breakage, Everpads solves this with a wider tungsten carbide base design, along with industry-leading tungsten carbide raw materials, optimized grain size, and a highly stable production process.

II. Beyond the Basics: Why T7WH is the Solution for Complex Milling Jobs

When selecting milling teeth for large machines, contractors often prioritize:

- Cutting efficiency – To ensure high-speed material removal.

- Fracture resistance – To prevent tool breakage in demanding conditions.

- A balance between both – For optimal performance across various terrains.

However, the real challenge in high-difficulty environments is that milling conditions vary widely. Many contractors struggle to find a single milling tooth that covers a broad range of applications without sacrificing performance.

We’ve observed two common issues in the market:

- Some brands design fracture-resistant teeth for extreme conditions, but compromise cutting efficiency due to shorter & wider tungsten carbide tips.

- Others prioritize cutting efficiency but fail to provide sufficient durability, leading to premature tool failure.

At Everpads, we don’t believe in compromises. That’s why we developed the T7WH, a milling tooth that delivers exceptional cutting efficiency while maintaining superior durability, making it the perfect choice for high-difficulty projects requiring broader applicability.

III. A Milling Tooth Without Compromise

Everpads is committed to customer-driven innovation, performance-first engineering, and never cutting corners. The GEN-E T7WH reflects that philosophy—delivering top-tier cutting efficiency, extended tool life, and industry-leading durability.

For contractors working in high-difficulty milling conditions, the T7WH is the ultimate solution—offering both precision and resilience for the most demanding projects.

📌 Still deciding which milling tooth to choose? Read our guide: "How to Evaluate Milling Teeth for Different Project Conditions" for expert insights!

Supplement Information

Understanding the Differences Between T7WH and T7WS

When choosing milling teeth for large machines, it’s essential to understand the distinct design philosophies behind T7WH and T7WS. While both models uphold Everpads' commitment to durability and efficiency, their structural differences make them suited for different milling conditions.

The T7WH is optimized for medium-to-hard surfaces, where impact resistance plays a crucial role. To handle these challenging conditions, it features:

- A reinforced carbide tip with a broader base, enhancing stability and impact resistance in high-stress applications.

- A slightly shorter but stronger carbide head, reducing breakage risks while maintaining cutting performance.

- A balanced design between fracture resistance and cutting efficiency, making it well-suited for demanding projects.

On the other hand, the T7WS is specifically designed for medium-soft environments, where cutting speed and penetration take precedence. It incorporates:

- A thinner, longer carbide tip, maximizing sharpness and material removal efficiency.

- A focus on sustained cutting performance, extending tool life while maintaining high-speed milling.

- A design that minimizes force resistance, making it ideal for applications where maximizing output is the goal.

Ultimately, T7WH is built for durability and adaptability in tougher conditions, while T7WS is designed for precision and efficiency in softer materials. Choosing between the two depends on the specific demands of your milling project and the operating environment.