The Most Dominant Choice for 1m Milling Machines – Engineered for Incomparable Durability

The Most Dominant Choice for 1m Milling Machines – Engineered for Incomparable Durability

When selecting the right milling teeth, contractors often focus on essential factors like tungsten carbide selection, manufacturing quality, alloy composition, and patented designs—all of which Everpads upholds to the highest industry standards.

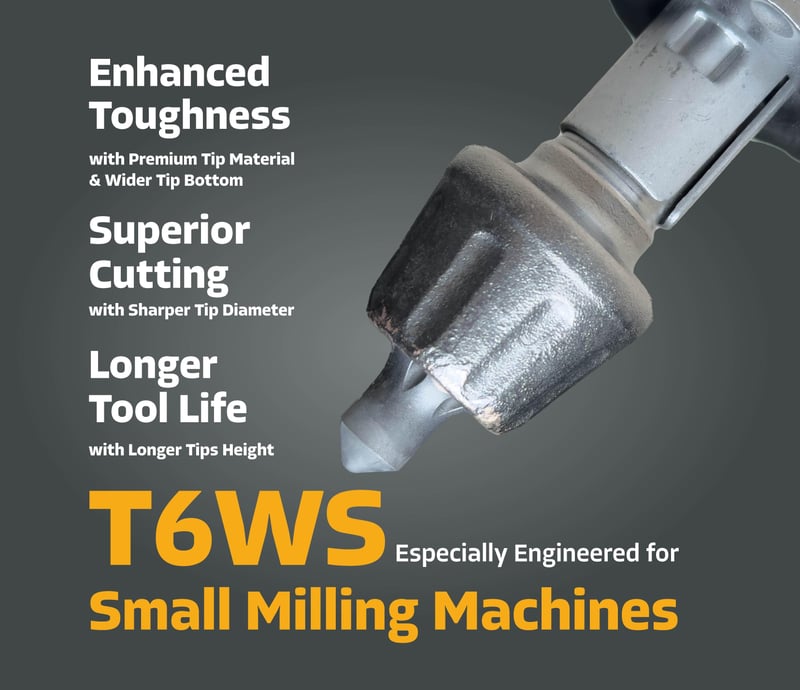

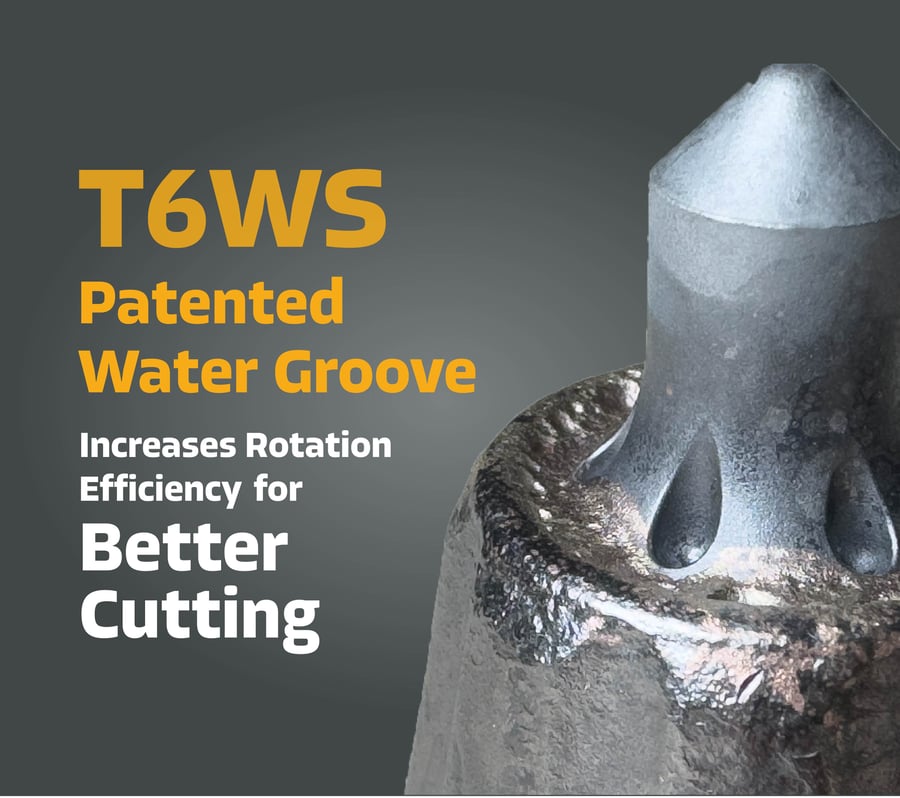

However, the real challenge begins after these fundamentals are met—choosing a milling tooth optimized for specific site conditions and performance needs. This is where GEN-E T6WS comes in, a milling tooth specifically engineered for small milling machines, ensuring maximum cutting efficiency, stability, and extended durability.

Top Economic Choice for Compact Machines

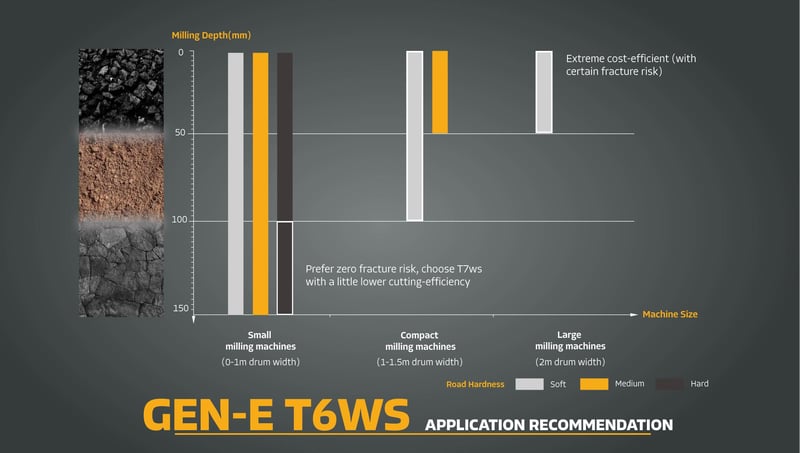

While T6WS dominates in small (1m) machines, it is also an optimal economic choice for compact milling machines (1.2m-1.5m) operating in medium-depth milling and softer conditions.

While T6WS is the enhanced version of T6w, optimized for small machines in full-depth milling applications, it is also highly recommended for:

- Compact milling machines in 0-100mm milling depth and soft conditions for cost-effective, high-efficiency milling.

- Compact milling machines for shallow milling in 0-50mm milling depth medium-hardness conditions.

- Large machines in 0-50mm milling depth and soft environments for extreme cost-effectiveness (with certain fracture risk)

📌 Want to learn how to evaluate milling teeth from different suppliers?

Read our expert guide: "How to Assess Milling Teeth Design and Materials Across Different Brands."

This blog is perfect for:

- Contractors and Operators looking for the most Durable and cutting-efficient milling teeth for small and Compact milling machines.

- Project Managers seeking to optimize milling performance while minimizing downtime and replacement costs.

I. How T6WS Stands Out from Competitor Products

Unlike competing products designed for the same applications, the T6WS introduces a revolutionary tungsten carbide design with superior durability and efficiency.

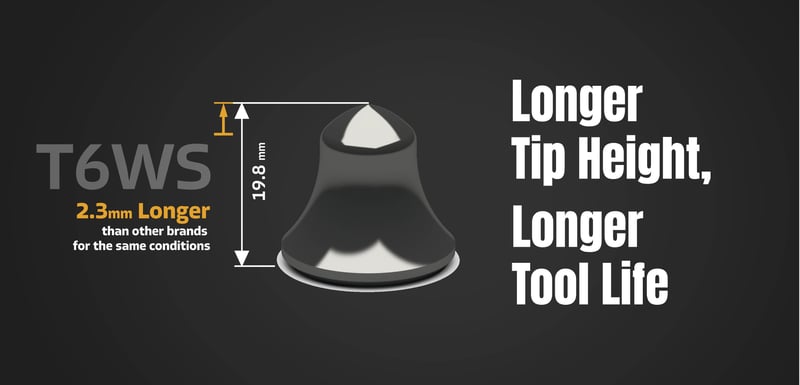

1. Incomparable Tool Life – 15% longer carbide tip than competitors, 10% longer than T6W, ensuring maximum wear life and stability.

2. Stronger Toughness– A 9% wider tip bottom provide the best impact resistance among products in this segment.

3. Stronger Toolholder Protection – A 10% wider base design extends toolholder lifespan by 15%.

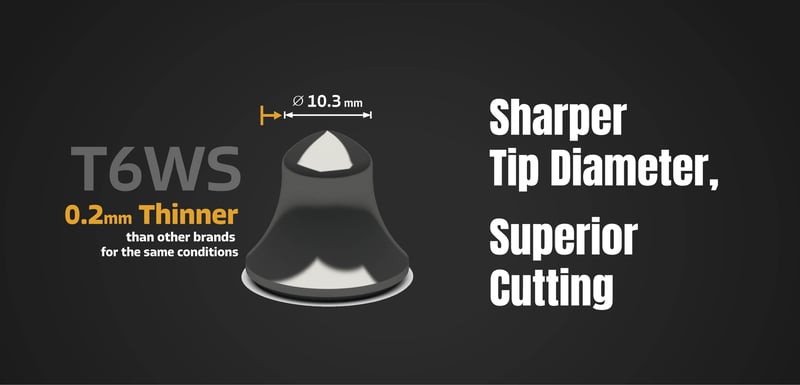

4. Industry-Leading Fracture Resistance – While thinner carbide tips are traditionally more prone to breakage, Everpads solves this through:

- A 9% wider tip bottom provide the best impact resistance among products in this segment.

- Premium-grade tungsten carbide selection

- Optimized grain size for impact absorption

5. Enhanced Cutting Efficiency –

A sharper tungsten carbide tip penetrates better, allowing for smoother and faster milling, even with lower-powered machines.

Patented Carbide Groove Design – Keeps cutting efficiency high for longer, reducing the frequency of tool replacements.

Compared to other top brands, the T6WS provides superior impact resistance while maintaining cutting performance. Most importantly, its extended carbide length results in a significantly longer lifespan than competitor products.

II. Meeting Higher Expectations: The Evolution from T6W to T6WS

While the T6W has nearly fulfilled the core needs of small milling machines and delivered performance beyond the highest industry standards, we have observed that customers have even higher expectations and demands.

Feedback from T6W users indicates that they are willing to invest more in durable milling teeth with lower replacement frequency to reduce machine downtime. Based on this, we have developed the T6WS, which offers a longer service life and greater impact resistance

III. When Choose T6WS Over T6W?

While the T6W has already set the industry standard for small machine milling, we have identified a growing demand for an even more durable milling tooth.

If you are searching for the best milling teeth experience for small machines in full-depth milling applications, then the economically friendly T6WS is YOUR ideal choice.

IV. A Milling Tooth to Dominate

At Everpads, we are committed to customer-driven innovation, prioritizing performance over cost-cutting. The GEN-E T6WS reflects this philosophy, delivering:

✔️ Unmatched cutting efficiency

✔️ Extended toolholder protection

✔️ Industry-leading durability

For contractors looking to maximize performance while reducing downtime, the T6WS is the ultimate solution.

📌 Still deciding which milling tooth to choose? Read our guide: "How to Evaluate Milling Teeth for Different Project Conditions" for expert insights!