Precision-Designed for Small Cold Milling Machines in Full Milling Applications

Choosing the right milling teeth isn’t just about tungsten carbide quality, manufacturing precision, alloy composition, and patented designs—all of which Everpads upholds at the highest industry standards.

Once these fundamentals are met, the real challenge is finding a milling tooth optimized for your specific applications. That’s where the GEN-E T6W stands out—a milling tooth designed specifically for small milling machines, ensuring maximum efficiency, stability, and durability in full milling operations.

While T6W is optimized for small machines in full milling applications, it is also highly recommended for:

- Compact milling machines (1-1.5m milling width) in 0-50mm milling depth and soft asphalt conditions

Note: Small machines (1m milling width) in extreme hard conditions and 100-150mm milling depth—

- T6ws is a better option for greater stability with equal cutting efficiency

- T7WS is also an alternative for greater stability but lower cutting efficiency

Note: This Guide is for road maintenance projects._%E5%B7%A5%E4%BD%9C%E5%8D%80%E5%9F%9F%201%20%E8%A4%87%E6%9C%AC%205-2.jpg?width=900&height=516&name=final_t6(Final%20Sean)_%E5%B7%A5%E4%BD%9C%E5%8D%80%E5%9F%9F%201%20%E8%A4%87%E6%9C%AC%205-2.jpg)

📌 Want to learn how to evaluate milling teeth from different suppliers?

Read our expert guide: "How to Assess Milling Teeth Design and Materials Across Different Brands."

📌 Want to learn more about milling tooth selection? Check out our guide: "How to Evaluate Milling Teeth for Different Project Conditions" for expert insights!

This blog is perfect for:

- ✔️ Contractors and Operators looking for the most cost-effective yet high-performance milling teeth for small and Compact milling machines.

- ✔️ Project Managers seeking to optimize milling performance while minimizing downtime and replacement costs.

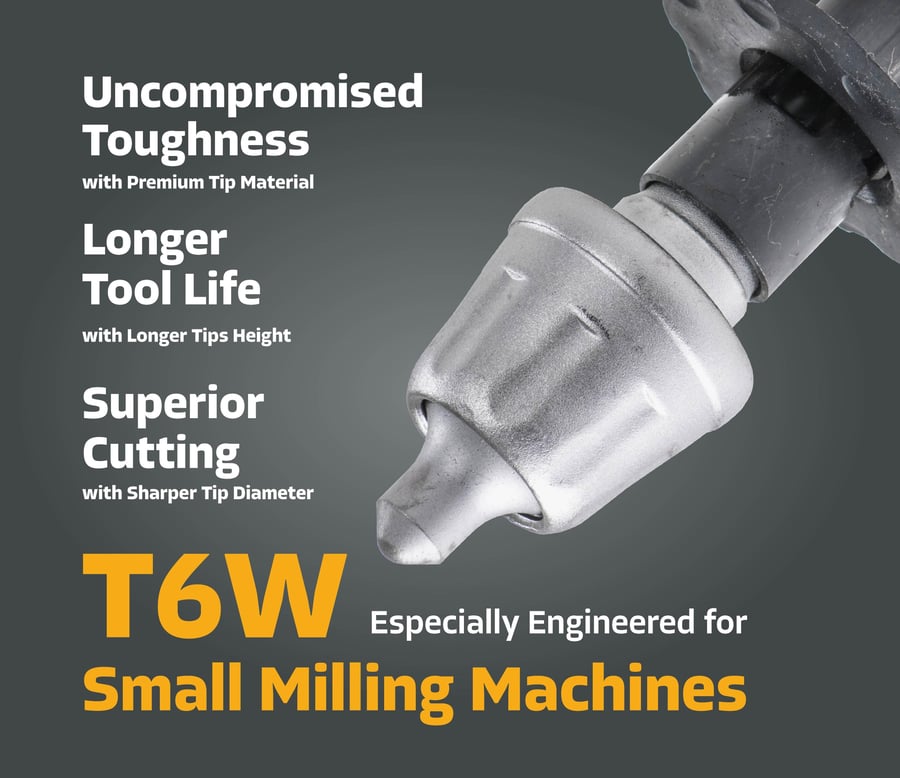

I. What Makes T6W Different?

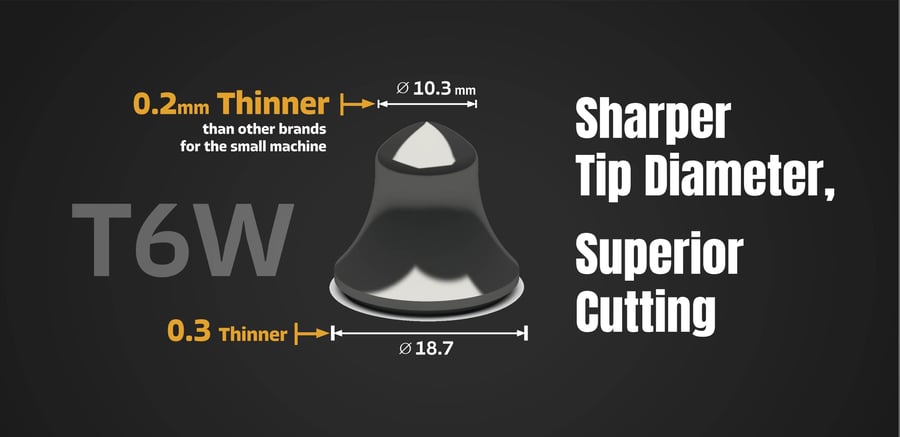

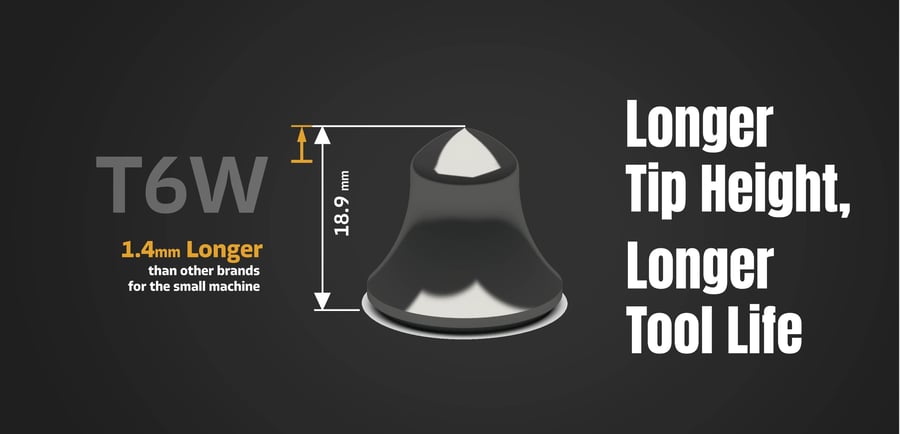

The T6W features a thinner yet longer tungsten carbide tip, setting it apart from other milling teeth designed for the same conditions. Here’s why that matters:

1. Enhanced Cutting Efficiency – A sharper tungsten carbide tip penetrates better, allowing for smoother and faster milling, even with lower-powered machines.

2. Extended Tool Life – A longer tungsten carbide tip means more wear material, increasing lifespan and reducing replacements.

3. Stronger Toolholder Protection – A 10% wider base design extends toolholder lifespan by 15%.

4. No Sacrifices on Fracture Resistance – While thinner carbide tips are traditionally more prone to breakage, Everpads solves this through:

- Premium-grade tungsten carbide selection

- Optimized grain size for impact absorption

- Stable manufacturing processes ensuring top-tier durability

-2.jpg?width=900&height=510&name=final_t6(Final%20Sean)-2.jpg)

5. Outperforms the Competition – T6W matches leading brands in fracture resistance while offering superior cutting performance. Plus, its longer carbide tip results in a longer service life than competing models.

II. Everpads Insight: Why We Designed the Gen-E T6w with These Key Features

When selecting milling teeth for small machines, contractors have different priorities:

- Some emphasize cutting efficiency to compensate for lower machine power.

- Others prioritize fracture resistance to extend tool life.

- Many seek a balance between durability and milling performance.

However, the real challenge for small machines is power limitations. Unlike large machines, small milling machines have lower torque and force output. Without the right cutting efficiency, poor milling performance can cause:

- Inefficient material removal, reducing productivity

- Excessive reactive impact force, leading to long-term machine damage

III. Beyond the Basics: Why T6W is the Solution for Complex Milling Jobs

We've noticed that some manufacturers increase tungsten carbide thickness to improve fracture resistance, but this sacrifices cutting efficiency—resulting in a major trade-off that compromises overall performance.

At Everpads, we reject compromise. That’s why we developed the T6W, a milling tooth that embodies our brand philosophy: customers should never have to choose between efficiency and durability.

IV. A Milling Tooth Without Compromise

At Everpads, we are dedicated to customer-driven innovation, prioritizing performance over cost-cutting. The GEN-E T6W reflects this philosophy, delivering superior cutting efficiency, longer tool life, and unwavering reliability.

The T6W is the ultimate solution for contractors who want to maximize milling performance on small cold milling machines without sacrificing stability.

V. When to Choose T6W Over T6WS?

While T6WS is designed for extreme conditions requiring higher durability, T6W remains the most cost-effective and efficient choice for contractors prioritizing affordability in small milling machines.