Revolutionizing Road Construction: Everpads' Gen-E Milling Drum For Cold Milling Machine

06. May. 2024

Everpads, a leading expert in road construction equipment parts, recognizes the significant costs of replacing a milling drum, not to mention the investment required for a new cold planer(Cold Milling Machine).

For over two decades, we have been dedicated to pioneering advancements in milling drum technology. With thousands of field tests, we continuously refine our systems to enhance milling performance. These developments have set new industry standards in durability, efficiency, and precision.

Our commitment to excellence ensures we address the real-world challenges of our clients, delivering projects of unmatched quality and cost-effectiveness.

This blog explores our latest innovations in milling drum technology, emphasizing our dedication to improving both the efficiency and durability of road construction. Our goal is to show how our focus on quality and innovation provides valuable, cost-effective solutions to industry challenges.

Ideal for contractors seeking to:

- Avoid the expense of new machinery by installing a high-performance milling drum.

- Revitalize aging milling equipment without sacrificing quality or affordability.

- Upgrade your current milling drum to a more advanced, high-performance model.

Oct%2cv2%20v5-1.png?width=504&height=430&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v5-1.png)

Table of Contents:

1. How EVERPADS Gen-E Milling Drum tackles the challenges?

2. Everpads' Manufacture Capability in Milling Drum Production

3. Comparative Analysis of Milling Drum Performance: Everpads vs. Others

4. Beyond the numbers: Everpads' Customized Design Service

5. Case Study: Gen-E Milling Drum Feedback from Jin-hua Road Construction Co, Ltd

6. Summary of Gen-E Milling Drum

Everpads' Solution in Milling Drum: How Gen-E Milling Drum Tackles the Challenges?

If you haven't delved into the challenges of milling drums, please read this blog: [Maximizing Savings for Cold Planer: A Guide to Milling Drum Replacement.]

1. PATENT Groove Geometry Shape of Base and TH12 Holder: The proprietary groove design provides extreme impact resistance to prevent any uncertainty from hard pavement materials or objects. This continues to secure the tightness of the tool holder system, maintaining it in the best condition and minimizing unexpected wear and tear during the milling operation.

2. Innovative Self-centering Base Hole for TH12 Holder:: To make milling drums even better, we have come out with a self-centering design for the TH12 tool holder and tool base. The goal of the design is to minimize the maintenance intervals of the tool holder to prevent wear and tear on the tool base screw hole. In comparison, throughout the service life of a milling drum, it usually required at least 15-20 tool holder replacements and even more screwing maintenance. EVERPADS' new patented design decreases the maintenance frequency to 8-12 times. The tool base can directly lock down the tool holder position through a mechanical design, not solely by the tool bolt. It significantly increases the service life of the milling drum and reduces labor costs.

3. Optimal Milling Base Alignment: Two decades of field testing have helped us identify the ideal alignment for milling bases, optimizing material removal and extending the lifespan of internal components.

4. Advanced Specific Automated 3D Positioning of Robotic Arms: We implement the most advanced tool base welding system to provide the most accurate tool base position and the angle. As a result, the milling surface is impeccable and satisfying. The milled texture consistently offers the best practice for our partner's project requirements.

5. Enhanced Surface Geometry for Increased Cutting Force Resistance: The optimized surface geometry of the tool base completely increases the contact surface area with the TH12 tool holder, enhances the maximum cutting force load, and minimizes unexpected wear and loosening.

Oct%2cv2%20v4_Oct%2cw3-2-2.jpg?width=482&height=318&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v4_Oct%2cw3-2-2.jpg)

6. Quality Assurance Through Dynamic Balancing: We employ sophisticated dynamic balancing machines to conduct detailed quality assessments of each drum, ensuring high standards are consistently met.

Everpads' Manufacture Capability in Milling Drum Production

Oct%2cv2%20v5-2.png?width=789&height=282&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v5-2.png)

1. Engineering Precision and Advanced Manufacturing: Everpads utilizes state-of-the-art 3D positioning robot arms and specialized multi-axis machining lathes, specifically engineered for the intricate task of producing milling drums. These technologies are essential for maintaining uniformity in welding angles and precision in base positioning, ensuring that each drum is perfectly aligned according to design specifications. This rigorous approach to engineering and manufacturing is crucial for creating products that meet the exact design requirements.

2. Design and Innovation in Mind: It is critical for manufacturers to demonstrate strong design and innovation capabilities, especially in optimizing base geometry and the strategic placement of these components. Such innovations significantly extend the service life of milling drums by enhancing their resistance to the rigorous conditions of milling operations. Without such capabilities, there is a risk of producing inferior drums.

3. Stringent Quality Assurance Measures: Everpads employs the Dynamic Balancing Machine to test each drum, ensuring a high level of quality control. This rigorous process is vital for maintaining uniformity and excellence across all products, with comprehensive inspections conducted at each stage of the production process.

4. Continuous Technological Advancement and Personnel Development: A proactive approach to technological investment and the ongoing professional development of staff is essential for spurring innovation and continual improvement in drum manufacturing techniques. Everpads is committed to adopting the latest technological solutions and offering continuous training opportunities for their staff, highlighting their dedication to maintaining high standards of manufacturing excellence.

2. Design and Innovation in Mind: It is critical for manufacturers to demonstrate strong design and innovation capabilities, especially in optimizing base geometry and the strategic placement of these components. Such innovations significantly extend the service life of milling drums by enhancing their resistance to the rigorous conditions of milling operations. Without such capabilities, there is a risk of producing inferior drums.

3. Stringent Quality Assurance Measures: Everpads employs the Dynamic Balancing Machine to test each drum, ensuring a high level of quality control. This rigorous process is vital for maintaining uniformity and excellence across all products, with comprehensive inspections conducted at each stage of the production process.

4. Continuous Technological Advancement and Personnel Development: A proactive approach to technological investment and the ongoing professional development of staff is essential for spurring innovation and continual improvement in drum manufacturing techniques. Everpads is committed to adopting the latest technological solutions and offering continuous training opportunities for their staff, highlighting their dedication to maintaining high standards of manufacturing excellence.

Comparative Analysis of Milling Drum Performance:

Everpads vs. Others

- Importance: Affects the expected longevity of a drum.

- Everpads' TH12 System: Screws need tightening only during installation.

- Others: Frequent tightening required as per the manufacturer's manual. Toward the end of their lifecycle, other brands' drums need even more frequent tightening due to increased looseness in the base screw holes.

2. Premature Failure Probability: The most common cause of premature failure is base hole wear, often due to loose screws during milling, and misalignment between holders and bases at the contact area. If you want to understand the principle in depth, please read this.

- Common Cause: Premature failure often results from base hole wear due to loose screws during milling and misalignment between holders and bases.

- Everpads' Approach: Uses a multi-axis lathe for precise alignment between holders and bases. The patented TH12 holder ensures screws remain tight during milling operations.

- Others: High-quality drums perform adequately if screws are promptly tightened; however, delayed tightening significantly increases failure risks. Lower-quality drums degrade quickly regardless of maintenance.

- Critical Aspect: Ensuring dynamic balance, which is fundamental for the effectiveness of drum rotation.

- Everpads' Method: Every milling drum is tested using advanced Dynamic Balance Machines to guarantee optimal balance and performance.

- Requirements: Precision in base positioning and consistent welding angles are crucial for achieving optimal milling patterns and long-lasting performance.

- Everpads' Technique: Employs 3D Auto Robot Arms for exact positioning and welding of drum bases, ensuring unparalleled precision. The patented TH12 system's groove geometry optimizes the contact area, enhancing force dispersion and maintaining base conditions for superior milling.

5. Maintenance Cost: This includes several aspects, including other component prices, labor costs, and machine downtime costs.

- Components Considered: Includes costs of components, labor, and machine downtime.

- Everpads' Advantage: Minimal screw tightening reduces overall maintenance. Components such as holders and teeth offer greater cost efficiency over time, especially when compared to other high-quality drum brands.

Explore Everpads solution for cutting tool: Everpads Technology- Gen-E Milling Teeth

Beyond the numbers: Everpads' Customized Design Service

There are former milling machine models that are hard to find corresponding drums to install, and we noticed they, therefore, we designed a service series to help our customers get the new corresponding drums that other manufacturers had not provided.Road construction companies face more and more challenges today. Our unique, newly designed milling drum provides outstanding performance that adapts to any road conditions. We meet the diversity of our customer's demands and frequently exceed their expectations.If you want to learn more, here is the link that discusses deeply with our solution:

Case Study: Gen-E Milling Drum Feedback from Jin-hua Road Construction Co, Ltd

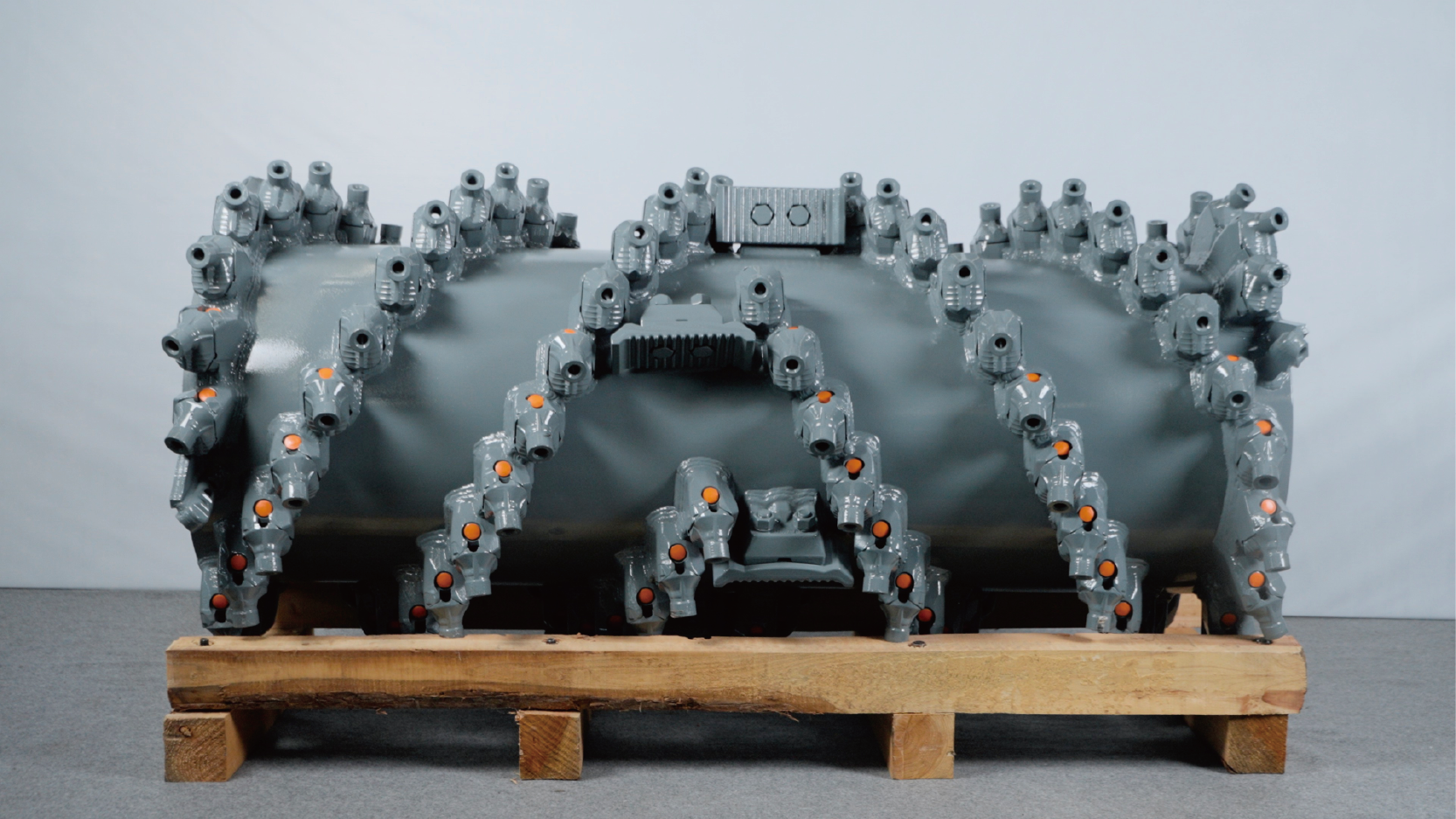

(FB:2200mm, LA:15mm, Max. FT:330mm, Teeth Quantity: 176)

This drum now has worked around 2000 hours in mostly AC mid, DEPT 10cm, and still shows no sign of base wear, and the picture below shows its high-quality results surface.

Oct%2cv2%20v4.jpg?width=789&height=303&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v4.jpg)

In addition, our concentration on manufacturing management makes our drums' manufacturing cost 60% less than the previous drum they used.

The value you will receive is a first-class, never-unexpected failure drum in the industry, and it only costs you 60% of the previous drums. This type of drum means around $30,000 dollars you will save immediately.

Oct%2cv2%20v5.jpg?width=789&height=295&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v5.jpg)

Gen-E Milling Drum

The insights, solutions, and benefits mentioned are not the last value we add to your business, the most important value is our 20-year reputation, brand vision, and mission.

Contact our sales team now for the most efficient drum in the industry!

Everpads never do empty talk, we research, we design, and we deliver.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)

Oct%2cv2%20v4_Oct%2cw3-2-3.jpg?width=482&height=299&name=(%E7%B5%82%E7%A8%BF)Oct%2cv2%20v4_Oct%2cw3-2-3.jpg)